Every OEM faces the same pressure — deliver innovative products faster, at lower cost and without compromising on quality. But achieving that balance isn’t easy, especially when production demands keep growing more complex.

Should you invest in your own manufacturing capabilities, or partner with a specialist to scale smarter?

In this guide, we break down both options — exploring the advantages, challenges and key factors that will help you choose the most efficient, resilient and profitable path forward for your business.

The case for outsourcing electronics manufacturing

Balancing innovation, cost and production efficiency is a constant challenge for OEMs. Partnering with a specialist contract electronics manufacturing provider can help you alleviate these pressures, enabling you to focus on your core strengths while ensuring high-quality, scalable production.

Here are seven key benefits that make outsourcing electronics manufacturing a compelling choice…

1. Access to advanced technology and expertise

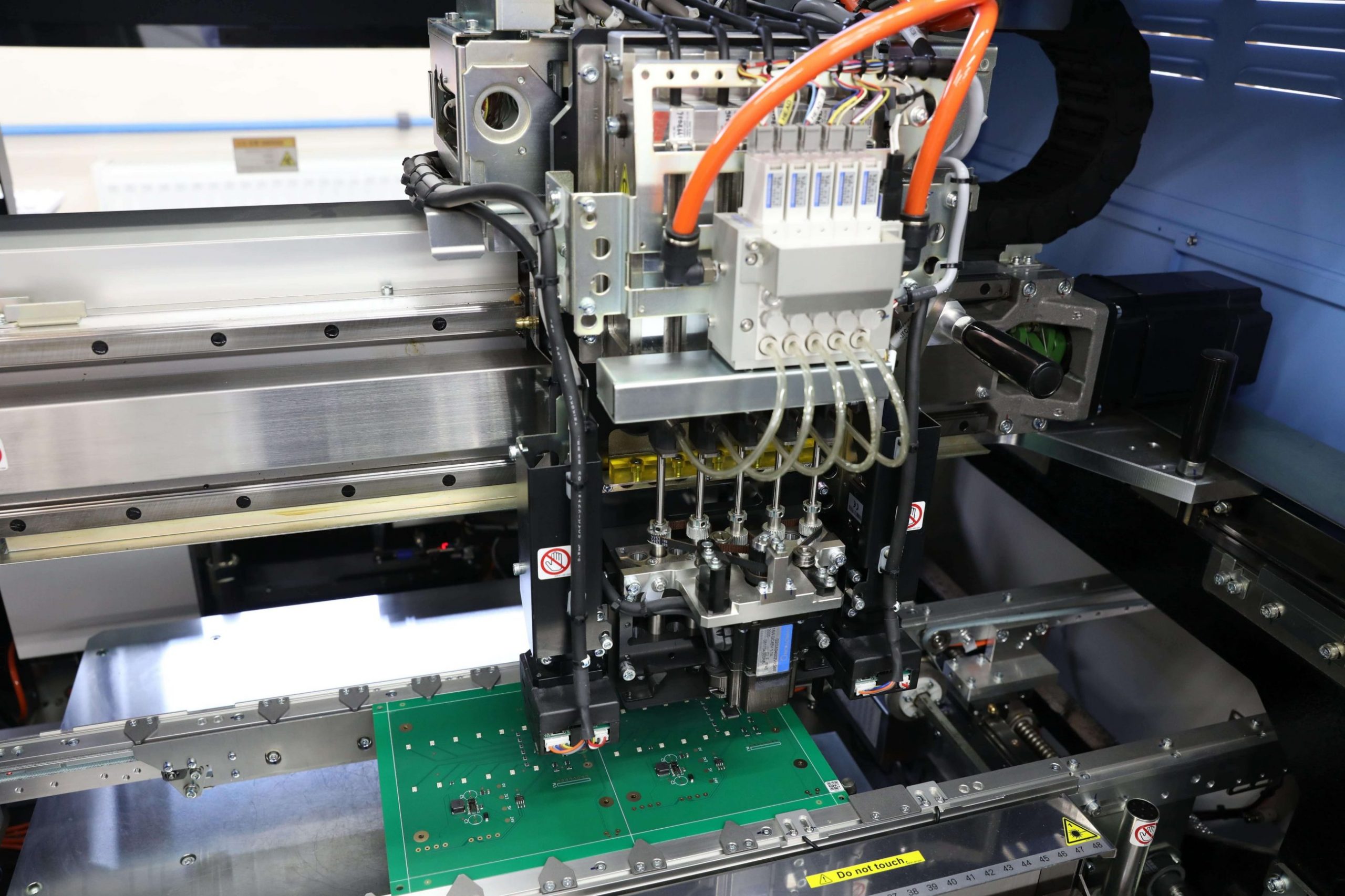

Staying current with the latest manufacturing technologies, testing methods and compliance standards demands significant investment. By leveraging electronic manufacturing services from an experienced partner, you gain immediate access to cutting-edge equipment, skilled engineers and proven processes. This eliminates the need for continuous capital expenditure and reduces the risk of falling behind competitors.

2. Reduced capital investment and overheads

Setting up and maintaining an in-house production facility is capital-intensive. Equipment purchases, facility maintenance and labour costs can drain resources that could otherwise fund R&D or market expansion.

Through contract electronics manufacturing, you can convert these fixed costs into variable costs — paying only for what you need, when you need it. This model improves cash flow and allows for greater financial flexibility, particularly during periods of fluctuating demand.

3. Faster time to market

Speed is a decisive factor in the electronics industry. Outsourcing streamlines the production process by leveraging the supplier’s established supply chains, efficient production workflows and scalable capacity.

With shorter prototyping and assembly times, you can bring products to market faster — gaining a crucial competitive edge and capturing opportunities before rivals.

4. Supply chain resilience and global reach

Managing a complex global supply chain can be a logistical burden for OEMs, especially when dealing with component shortages or geopolitical disruptions. Reputable electronics manufacturing companies have established networks of suppliers and procurement strategies that mitigate these risks. They can source components globally, manage inventory and ensure consistent production flow even in uncertain conditions.

5. Quality assurance and compliance

Quality control and regulatory compliance are essential but resource-heavy aspects of production. Leading contract electronics manufacturing partners operate under stringent quality standards, such as ISO 9001, IPC-A-610 and RoHS compliance. Their expertise ensures every product meets or exceeds industry benchmarks, reducing the likelihood of costly recalls or reputational damage.

6. Scalability and flexibility

Demand for electronic products often fluctuates, making in-house capacity planning a challenge. Outsourcing electronics manufacturing allows you to scale production up or down without major disruptions or investment in additional infrastructure. This flexibility ensures you can respond quickly to market shifts, seasonal spikes or new product launches.

7. Focus on core competencies

By entrusting production to an outsourced partner, you can redirect time and resources to areas that drive competitive advantage — such as product design, innovation and customer engagement. The result is a leaner, more strategic organisation that prioritises growth and market leadership over operational complexity.

Why some OEMs keep production in-house

While outsourcing electronics manufacturing offers clear advantages, there are reasons why some OEMs choose to retain full control of their production. Managing operations internally can deliver benefits in areas such as intellectual property protection, quality control, and strategic agility.

Below are five common reasons why some OEMs choose to keep manufacturing in-house.

1. Greater control over quality and processes

When manufacturing is managed internally, you have direct oversight of every stage of production — from sourcing components to final testing. This allows for immediate intervention when issues arise and ensures strict adherence to company-specific quality standards. It also gives you the ability to directly implement and monitor sustainable practices, such as responsible material sourcing, energy-efficient operations and waste reduction initiatives that align with your organisation’s environmental goals.

2. Enhanced intellectual property protection

For OEMs developing proprietary designs, algorithms or sensitive technologies, intellectual property (IP) security is crucial. Outsourced partners generally operate under non-disclosure agreements, but outsourcing can still introduce a level of risk.

In-house production keeps all IP, design files and technical know-how within your organisation — providing peace of mind for products where confidentiality is critical.

3. Tighter integration between design and production

When engineering and manufacturing teams operate under one roof, communication can flow more seamlessly. Design changes can be tested, validated and implemented quickly, reducing the back-and-forth that sometimes occurs with third-party electronic manufacturing services.

This integration fosters innovation, accelerates design validation and ensures that manufacturing feedback directly informs future product development.

4. Building internal expertise and capability

Retaining manufacturing internally helps you develop deep technical expertise and process knowledge. This internal capability can become a strategic asset, enabling more informed decision-making, stronger supplier management and greater long-term independence from third-party vendors. It also nurtures a skilled workforce that contributes to your innovation culture and competitive edge.

5. Brand and quality reputation

For many OEMs, brand reputation is built on reliability, precision and performance. Managing production internally allows for meticulous oversight and ensures that every product reflects your standards and values. By keeping manufacturing in-house, you maintain full accountability for product integrity.

Selecting the best electronics manufacturing route for you

Success lies in choosing the right partner — one that aligns with your business values, technical needs and sustainability objectives.

| Consideration | Outsourcing (Contract Electronics Manufacturing) | In-House Manufacturing |

| Access to technology & expertise | Immediate access to advanced equipment, skilled engineers and up-to-date compliance knowledge through electronics manufacturing services providers. | Requires continuous investment in new technology, training and compliance expertise. |

| Capital investment & overheads | Converts fixed costs into variable costs — pay only for what you need, improving cash flow and financial flexibility. | High initial setup and ongoing operational costs; more control but heavier financial burden. |

| Speed & time to market | Established supply chains and scalable capacity reduce lead times and accelerate product launches. | Slower production ramp-up, especially when capacity or staff are limited. |

| Supply chain & scalability | Global networks enhance supply chain resilience; easy to scale up or down as demand changes. | Scaling requires new equipment or workforce expansion — often costly and time-consuming. |

| Quality & compliance | Experienced partners follow strict standards (ISO 9001, IPC-A-610, RoHS), ensuring consistency and reliability. | Direct control over processes; quality depends entirely on internal systems and expertise. |

| Intellectual property (IP) security | Protected by NDAs but involves sharing data with third parties. | Full IP control stays within the organisation, reducing exposure risk. |

| Design & production integration | External collaboration may create communication gaps, though strong partners mitigate this. | Seamless collaboration between design and production teams; faster design iteration. |

| Internal expertise & capability | Frees resources to focus on design and innovation rather than production. | Builds in-house technical knowledge and long-term capability. |

| Brand & product accountability | Quality depends on partner selection — choose trusted providers with strong track records. | Full accountability and brand control over every stage of production. |

| Sustainability & environmental control | Can be achieved by selecting a sustainable electronics manufacturer with clear ESG commitments. | Direct control over materials, energy use and waste management practices. |

How to choose the right contract electronics manufacturing partner

The ideal partner balances the benefits of outsourcing with the advantages of in-house production.

Here’s what to consider when choosing a manufacturing partner…

Proven expertise and industry experience

Look for a partner with a solid track record in your specific market segment, whether that’s industrial, medical, automotive or consumer electronics.

An established provider will understand the compliance standards, certifications and performance expectations relevant to your sector. Their technical proficiency, combined with specialised knowledge, reduces risk and ensures your product meets both regulatory and end-user demands.

Comprehensive service offering

A good partner should offer more than just assembly. The most effective relationships are built around a complete suite of electronic manufacturing services — from design for manufacturability (DFM) and prototyping to printed circuit board (PCB) assembly, testing, supply chain management and after-sales support. This end-to-end capability allows you to consolidate operations under one trusted provider, improving efficiency, communication and overall product consistency.

Scalability and flexibility

Your manufacturing needs will evolve over time. The right partner should have the infrastructure and capacity to scale production up or down as demand changes, without compromising on quality or lead times.

A scalable partner can grow with your business, supporting both new product launches and long-term production stability.

Commitment to quality and compliance

Certifications such as IPC-A-610 for PCB assemblies and IPC/WHMA-A-620 for cable assemblies indicate a manufacturer’s dedication to quality. Ask about their inspection procedures, traceability systems and approach to continuous improvement. The best partners invest in robust quality control and testing processes, ensuring that every board and component meets your specifications and industry standards.

Transparency and communication

A trusted partner should provide regular progress updates, offer visibility into their supply chain and respond quickly to changes or issues. Transparency promotes collaboration — allowing you to enjoy the responsiveness of an in-house team while benefiting from the scalability and efficiency of outsourcing electronics manufacturing.

Sustainability and ethical practices

As environmental and social responsibility become central to business strategy, working with a sustainable electronics manufacturer can significantly enhance your brand reputation and long-term viability.

Evaluate potential partners on their environmental management systems, energy efficiency initiatives, waste reduction practices and ethical sourcing policies. A sustainable electronics manufacturer not only reduces your carbon footprint but can also help you meet global compliance standards, such as RoHS, REACH and WEEE.

Financial stability and long-term partnership potential

Finally, ensure that your chosen partner is financially stable and committed to long-term collaboration. Contract electronics manufacturing is a partnership built on trust — and reliability is essential to avoid production delays or disruptions. A stable partner can invest in technology, workforce training and capacity expansion that support your growth over time.

What to look for in a contract electronics manufacturer: a quick checklist

For OEMs focused on innovation, cost efficiency and rapid scalability, partnering with an outsourced provider can unlock significant operational and financial benefits. It allows your teams to concentrate on product design and market growth while leveraging external expertise in production, quality assurance and supply chain management.

When looking for an outsourcing partner, you should consider the following essentials:

- Proven experience in your market sector (industrial, medical, automotive, etc.)

- Comprehensive service range — from design and prototyping to assembly, testing and logistics

- Scalable capacity to handle demand fluctuations and product growth

- Quality certifications, such as ISO 9001, IPC-A-610, and RoHS compliance

- Transparent communication and strong project management systems

- Financial stability and a track record of long-term partnerships

- Sustainability credentials — choose a sustainable electronics manufacturer with ethical sourcing and eco-efficient practices

Leading contract electronics manufacturing solutions for OEMs

Whether you build in-house, outsource completely or pursue a blended model, aligning your manufacturing strategy with your business goals is key to long-term success.

Many OEMs hesitate to embrace outsourced electronics manufacturing because they fear losing control over quality, flexibility or visibility — but EC Electronics eliminates these concerns.

With nearly four decades of experience delivering comprehensive electronic manufacturing services, EC combines the rigour of in-house standards with the efficiency of a global supply chain.

Certified to ISO 9001 and ISO 14001, and with IPC-A-610 and IPC/WHMA-A-620 qualified staff, EC ensures quality, compliance and reliability. Our multi-site operations in the UK, Netherlands and Romania also offer scalable capacity and local responsiveness, giving you the agility of in-house production without the overhead. Plus, as a sustainable electronics manufacturer, EC prioritises ethical sourcing, waste reduction and environmental responsibility.

In short, EC Electronics offers you all the control and confidence of in-house manufacturing — with the added benefits of flexibility, cost efficiency and end-to-end capability.

EC Electronics is the UK’s leading contract electronics manufacturing provider for OEMs working across a range of industries. Contact us today to see how we can help you streamline operations, control costs and maintain consistent quality with our electronics manufacturing services