Once upon a time, the idea of coexisting with robots was a futuristic fantasy. But in 2023, we are coming closer and closer to making this dream a reality…

Electronics automation has come on leaps and bounds in recent years thanks to the rapidly expanding capabilities of Industry 4.0 technologies like the internet of things (IoT), artificial intelligence (AI) and 5G networking.

As a result, we are seeing incredible progress in robotics, particularly within the industrial sector. Most individuals and businesses already benefit from robotics and automation in some way — from self-navigating vacuum cleaners to collaborative robots that work alongside people in a range of factory settings — and the best is yet to come.

So, what can we expect from the robotics industry in the coming months and years — and what will this enhanced automation allow businesses to achieve?

A new dawn for robotics

The robotics industry is about to go stratospheric.

According to GlobalData research, it was worth $52.9 billion (£42.8 billion) in 2021 and will reach $568 billion (£460 billion) by 2030, registering a compound annual growth rate (CAGR) of 30%. But what is driving this impressive growth?

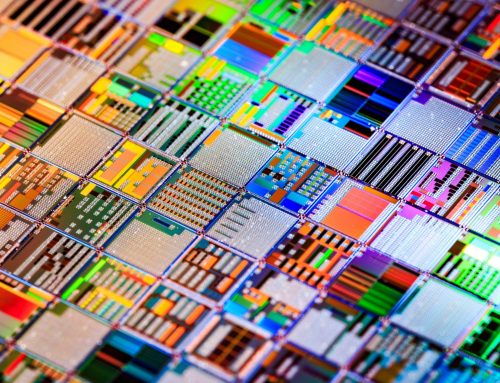

Humans have been developing robots for decades — from simple assembly machines to human-looking androids. However, progress in this field has accelerated dramatically in recent years due to the demand for digitisation, high levels of connectivity and improvements to electronics manufacturing processes.

The miniaturisation of technology combined with enhancements to network infrastructure has created new possibilities for product designers. Not only are devices getting smaller and more efficient, but they can also perform more independent functions than ever, with intelligent IoT sensors and wireless connectivity facilitating advanced automation.

As a result, robotics products are becoming more intertwined with our daily lives. You can already find these machines in almost every sector, including healthcare, entertainment, manufacturing and travel, and it looks like this is only the beginning.

Robotics are reaching new levels of cognitive ability, increasing the likelihood of machines working alongside people to conduct tasks that are monotonous, dangerous or require extreme precision. And with the imminent rollout of 5G networks, cloud robotics will soon be untethered from wired internet networks and able to transmit large amounts of data in no time — meaning more complex automation, easier maintenance and faster functionality.

In light of these upcoming developments, it is no wonder that robotics and automated systems will account for an estimated 25% of industrial capital spending over the next five years.

So, what sectors stand to gain from this technology, and what obstacles will they need to overcome to ensure its safe and sustainable deployment?

The next steps for automation

The main advantage of modern robotics is the ability to automate repetitive and high-volume tasks to a high degree of accuracy, increasing productivity and minimising human error.

These features are especially beneficial for industrial sectors such as automotive and manufacturing, where robots are already supporting workloads. And as the capabilities of AI, wireless networking and natural language processing improve, we can expect to see them in more applications where automation can bolster efficiency and cut costs — especially amidst supply chain issues and labour shortages.

For example, the pandemic gave momentum to automation in healthcare, with robots used to assist with anything from delivering supplies to conducting surgeries. Moving forward, social robots — a type of ‘friendly’ autonomous mobile robot (AMR) — will help alleviate burdens on healthcare staff. They could even begin interacting with patients in hospitals and long-term care environments, providing helpful information and behavioural monitoring.

Of course, designing and manufacturing robotics is no simple task. Some robotics technology is still unfamiliar, and robotics designers must upskill to keep pace with development and ensure every component performs at the highest level of safety, consistency and efficiency. Plus, there are several cyber security considerations to keep in mind — especially as robotics relies more heavily on cloud-based networking.

Still, the shift to an autonomous world seems inevitable, with more ‘smart’ technology solutions emerging each year. So, if you are interested in capitalising on this ever-growing market, now is the time to act…

At EC Electronics, we know how to design and deliver electronics for the robotics sector that meet every expectation for precision and quality. Take a look at our robotics and automation page today and give us a call at +44 (0)1256 461894 to discuss our electronics manufacturing