It is no secret that robotics are becoming more intertwined with our daily lives.

You can already find these machines in almost every sector, including healthcare, entertainment, manufacturing and travel — and it looks like this is only the beginning.

Thanks to the rapidly expanding capabilities of Industry 4.0 technologies like the internet of things (IoT) and artificial intelligence (AI), the reality of machines working alongside people is becoming a fast reality…

With the imminent rollout of 5G networks, cloud robotics will soon be untethered from wired internet networks and able to transmit large amounts of data in no time — meaning more complex electronic automation, easier maintenance and faster functionality.

In light of these upcoming developments, it is no wonder that robotics and automated systems will account for an estimated 25% of industrial capital spending over the next five years.

So, how are industries already benefitting from robotics and how can product designers ensure their safe and sustainable deployment?

Discovering robotics applications

Until recently, robots were primarily used to assemble cars in automotive factories. However, as technology progresses, so too does the scope of robotics…

According to Geordie Rose, the chief executive of Sanctuary AI, the development of robots for household chores and general-purpose tasks is less than 10 years away!

In the hopes of levelling up from a trial project in March 2023, where a robot undertook 110 retail-related tasks like folding, cleaning and picking and packaging merchandise, Sanctuary AI plans to use film to train its humanoid robot — making it even more agile and efficient.

Robotics are not limited to the retail sector, either. A hospital in London has become the first in the UK to complete 10,000 operations using a surgical robot. In fact, almost all prostate, kidney and lung cancer surgeries throughout the hospital are now completed robotically.

No matter the industry, robotics are reaching new levels of cognitive ability.

The miniaturisation of technology combined with enhancements to network infrastructure has created new possibilities for product designers, allowing robotics to perform more independent functions than ever — with intelligent IoT sensors and wireless connectivity facilitating advanced electronics automation.

Now, machines can conduct monotonous duties to free up workers’ time, carry out dangerous jobs involving toxic substances or handling heavy loads and execute tasks requiring extreme precision to minimise human error.

So, it is no surprise that manufacturing these revolutionary robotics should be done with expert care…

Delivering quality and innovation

With the popularity of these autonomous machines set to grow, we expect to see high investment volumes for robotics projects in the coming years.

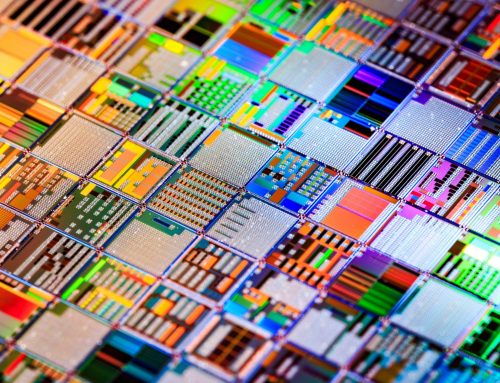

But designing and manufacturing robotics is no simple task. The next generation of robots will consist of increasingly complex electrical systems — especially as printed circuit boards (PCBs) and sensors continue to shrink.

Plus, due to the precise and often high-risk nature of many robotics applications, every component must perform at the highest safety, consistency and efficiency level. So, before developing a robotics product of your own, it is crucial to choose an electronics manufacturer that can meet these requirements…

At EC Electronics, we know how to design and deliver electronics for the robotics sector that meet every expectation for precision and quality.

Our quality management systems (QMS) are certified in line with EN ISO/IEC 80079-34:2018 standards, and our team of IPC-A-610 and IPC/WHMA-A-620 certified specialists ensure safety and reliability for all products.

Are you ready to bring your robotics and automation concept to life? Discover how our electronics manufacturing services can assistance your project and call +44 (0)1256 461894 to discuss your requirements.