As you read this, scientists are working to find solutions to our world’s greatest challenges, like climate change, healthcare and global hunger. But in their pursuit of research and development victories, scientists must also face many complexities…

Increasingly stringent compliance regulations. Tightened budgets. Staff shortages. Scientific instruments maintenance. Juggling these challenges outside of their research takes time and expertise — resources that are hard to expend in the fast-paced world of science.

That is where laboratory automation comes in.

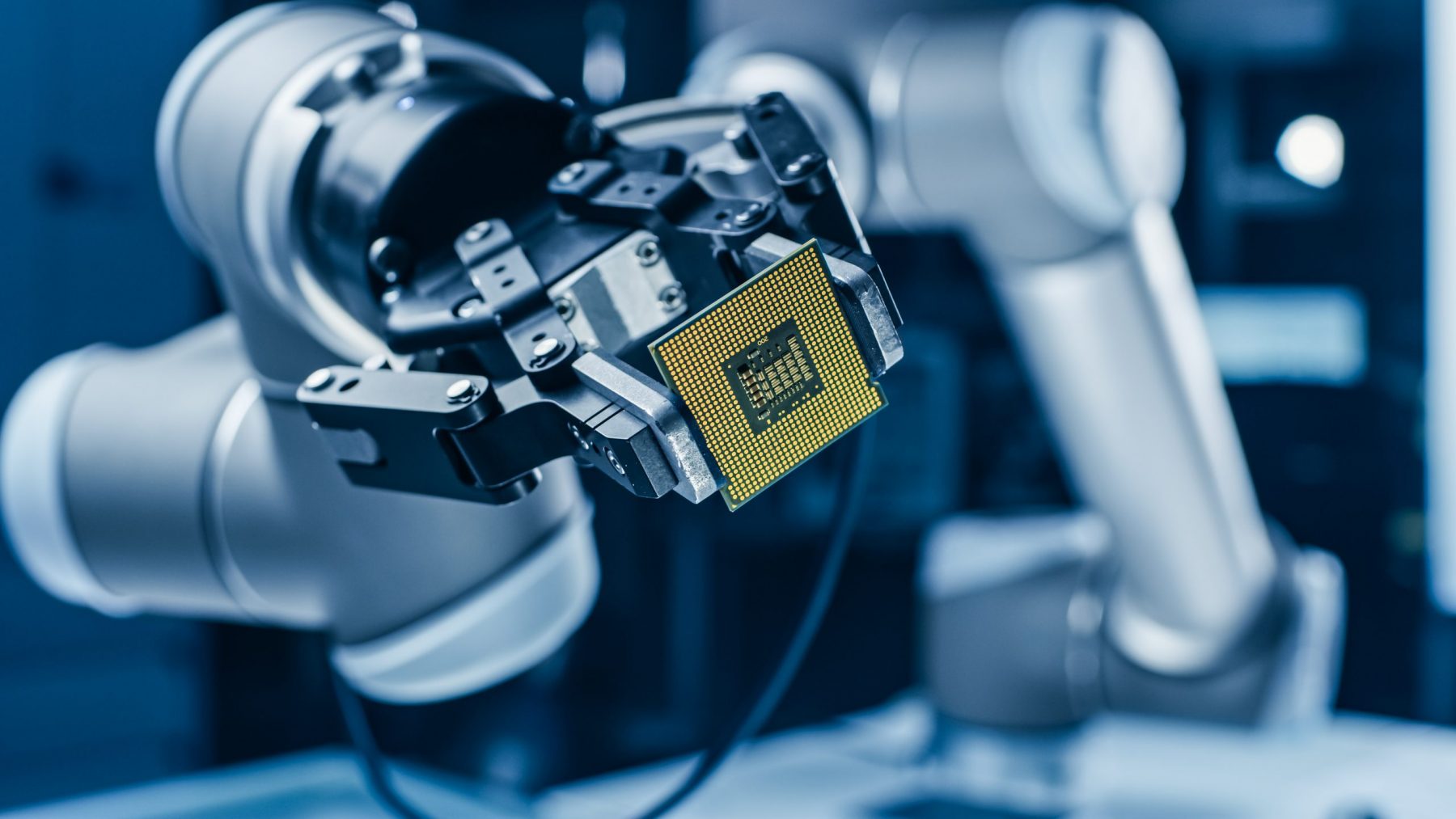

Through advanced technologies like robotics, sensors and computers, lab automation encompasses the integration of artificial intelligence (AI), machine learning (ML) and data analytics to increase productivity, streamline workflows and reduce human error.

So, what can these advanced technologies offer to meet the demands of modern labs — and how are they being used today?

The (many) benefits of lab automation

Despite the ever-changing demands of scientific research and development, lab automation provides consistent advantages.

Expanded lab capabilities

Utilising automated software and robots expands the capabilities of laboratories, giving researchers increased capacity to complete complex tasks that require human insights and offering assistance on repetitive tasks.

Guaranteed reproducibility

Automation tools have the potential to reduce human error, variability and substance contamination — resulting in better quality and more accurate results.

For example, laboratory automation can enable a greater rate of experimental data capture, increased volume of results and the use of a broader range of controls, which helps to increase the chances of results being reproducible. This reliable data can then be built upon with further research.

Improved data accuracy

Automation tools use AI and ML algorithms to learn from a large pool of real data samples. By utilising these tools, researchers can improve the accuracy of data evaluation compared to human-based interpretations.

Plus, since data logging is time-intensive and mundane, it can be easy for lab workers to make mistakes. Automating this process helps guarantee up-to-date, accurate data that is available to investigate in real-time.

Most importantly for scientists, accurate data is essential for traceability and compliance purposes.

Safer working conditions

As many lab processes are hazardous and involve exposure to dangerous liquids and chemicals, automating the handling of these substances can create a safer work environment.

Introducing automation can even help modern researchers become more eco-conscious since their experiments will consequently use up less energy and create less waste.

Key lab automation technologies

Whilst automated systems can get quite expensive, many labs are taking advantage of more budget-friendly options that do not require fully automated workstations to get the job done…

For instance, incubators are among the most common types of automated scientific instrumentation. This equipment requires reliable electronics that create a controlled and contaminant-free environment for the growth of cell and tissue cultures. The incubator’s microcontroller processes data from precise temperature and humidity sensors to automate and control the conditions of the incubator. When the microcontroller notices a change in these conditions, it can activate the fan or lamp.

Another widespread use of automation in the lab is high-throughput screening. In drug discovery and development, researchers are tasked with testing thousands of compounds to identify potential drug candidates. Lab automation, such as liquid handling robots and plate readers, can speed up the process by quickly and accurately screening large numbers of compounds.

Sample preparation and tracking is another time-consuming and error-prone job. Luckily, automated sample preparation systems can increase productivity and accuracy. Lab workers may also utilise automated systems incorporating barcoding and scanning technologies, which allow them to track samples throughout the lab workflow and ensure accurate identification, sample routing, and traceability.

Importance of high-quality manufacturing

When it comes to scientific instruments and laboratory automation, there are three essential factors: reliability, safety and user-friendliness.

These vital tools must meet strict specifications and there is no tolerance for error. So, finding an electronics manufacturing services (EMS) provider with an established track record of developing high-quality products for scientific environments is crucial…

At EC Electronics, we are well-versed in manufacturing PCB assemblies, cable assemblies and electronics box builds for use in instruments across a range of scientific research applications.

Our industrial and scientific instrumentation customers continue to use our services because we offer a truly bespoke service — as well as flexibility, advanced electronics manufacturing capabilities and a commitment to consistent quality.

Our quality management systems (QMS) are certified in line with EN ISO/IEC 80079-34:2018 standards, meaning your electronics are manufactured to the highest specifications, and our team of IPC-A-610 and IPC/WHMA-A-620 certified specialists ensure reliability for all products in high-risk applications.

Our electronics manufacturing team can support your next scientific instrument project for an automated lab from concept to reality — bringing it to market competitively through our product realisation service. To discuss your requirements, get in touch at 01256 461894 or email sales@ecelectronics.com.