Manufacturing robust, reliable electronic products requires more than just printed circuit boards and mechanical housings — cable assembly is a critical link that ensures power, signal integrity and connectivity between subsystems.

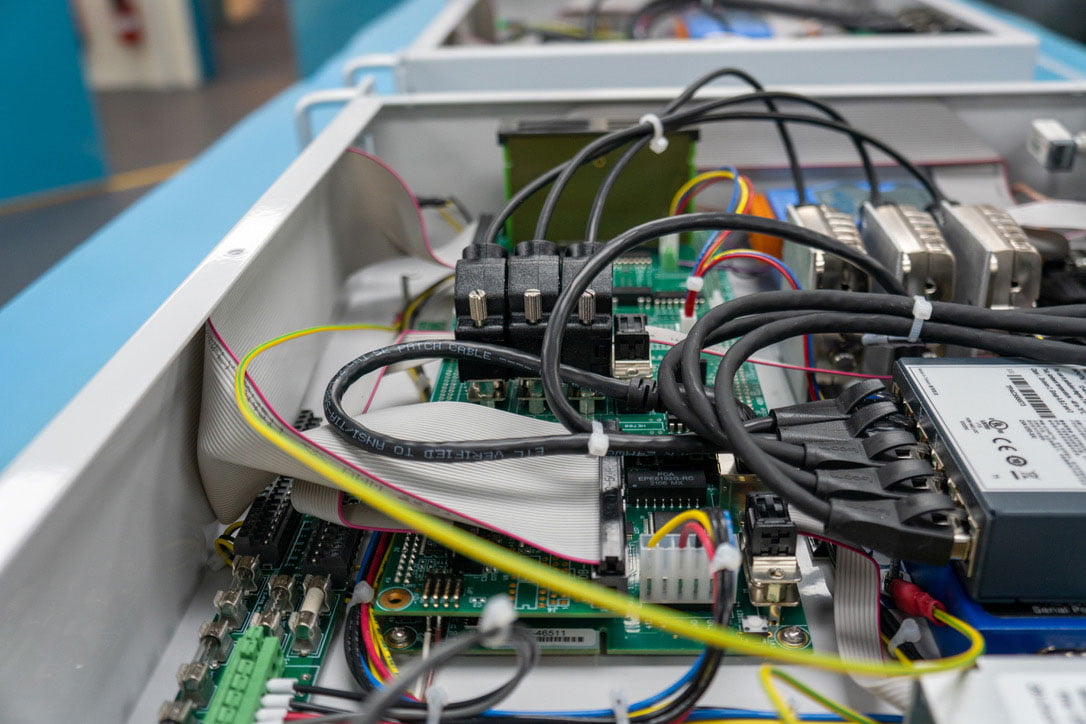

Whether you’re an original equipment manufacturer (OEM) designing for automotive control units, marine navigation systems or industrial automation equipment, the interconnect harness is what holds the entire system together. Cable assemblies directly impact product performance, safety and longevity, so it’s essential to use quality cable assemblies.

In this guide, you’ll learn the key factors that determine cable assembly quality in different industries and understand how to specify, test and procure cable assemblies that meet demanding requirements.

By the end of this guide, you’ll know why partnering with an experienced electronics manufacturer can streamline your production and what to look out for in an electronics manufacturing services provider.

Key considerations for quality cable assembly

Whether you’re ordering standard off-the-shelf looms or specifying a fully custom cable assembly, several core factors affect quality, cost and time-to-market. Below, we break down the most important considerations and how they can vary by industry.

Material selection and conductor construction

To manufacture high-quality cable assemblies, you need to select the right materials and construction techniques.

Over-sizing conductors can increase cost while under-sizing can risk overheating, which could lead to costly recalls further down the line. So, it’s important to consider the conductor type and gauge to minimise voltage drop under load and prevent overheating and the risk of premature failure. Tin-plated copper conductors, for example, are common in electronics products that need to resist corrosion.

Insulation and jacketing materials are also crucial to cable assembly performance, particularly in harsh environments. A standard PVC jacket can suffice for low-voltage signal lines in controlled settings, but applications that see elevated temperatures — such as power electronics — may require cross-linked polyethene (XLPE) or thermoplastic elastomer (TPE). Marine electronics often rely on fluoropolymers like PTFE or FEP to resist chemicals and saltwater. Similarly, industrial tendon or robotic arm systems frequently specify thermoplastic polyurethane (TPU) or heavy‐duty PVC jackets for abrasion resistance against moving parts.

Shielding choices also play a crucial role in preserving signal integrity in cable assemblies. Automotive infotainment cables typically employ foil shields for 100% coverage, whereas high-speed data lines in industrial networks might use braided copper shields with 80–95 % coverage to protect against electromagnetic interference (EMI).

Connector selection and termination methods

Connector selection and termination techniques are equally important. For instance, marine systems often lean on IP68-rated circular connectors that prevent water ingress.

Termination methods — whether crimping or soldering — must be chosen based on volume, mechanical stress and the conductor type. A precise crimp, executed by a calibrated press and inspected using pull-test fixtures, can yield a safer connection than a hand-soldered joint, though low-volume or highly specialised prototype cable assemblies may still use soldered terminations to accommodate unique pin layouts. Whenever connectors mate directly to a printed circuit board (PCB), wire-to-board pin headers require careful solder fillets and strain relief to prevent joint fatigue during service.

Proper strain relief is non-negotiable in applications where cables flex, vibrate or endure repeated motion. This is where overmoulding and low-pressure overmoulding come into play. Overmoulding encapsulates the connector-cable junction in a durable thermoplastic or thermoset compound, creating a seamless transition that mitigates mechanical stress. In contrast, low-pressure overmoulding uses hot-melt polyamide injected at much lower pressures so that delicate PCB-mounted terminations are not stressed by high injection forces. Both approaches seal against moisture and dust, helping assemblies achieve IP67 or IP68 ratings.

OEMs in automotive or marine sectors often specify overmoulding to ensure reliability under hood heat or submersion, while select industrial controls that require PCB-level cabling rely on low-pressure overmoulding to protect against contaminants without risking solder joint damage.

Testing and compliance

Ensuring the cable assembly meets the demands of the application begins with a framework of certifications and standardised testing protocols. An ISO 9001–certified quality management system provides the procedural controls, process audits and continual improvement mechanisms needed to maintain consistency across multiple production sites.

When combined with ISO 14001–based environmental management, manufacturers can guarantee that both materials and processes adhere not only to performance requirements but also to environmental regulations, such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals). This dual-certification approach ensures every cable assembly produced complies with electrical, mechanical and ecological standards from the moment raw materials enter the facility until finished harnesses depart.

Because many OEMs create electronics for safety-critical systems, it is also essential that all interconnects be designed, manufactured and tested according to recognised industry specifications. Manufacturers operating in these environments should work to IPC/WHMA-A-620 Class 3, which is specifically designed to define quality criteria for cable and wire harness assemblies used in high-reliability or mission-critical products. In addition, compliance with the ATEX Directive 2014/34/EU ensures cable assemblies destined for explosive or potentially combustible environments (such as oil and gas drilling platforms or chemical processing facilities) are constructed with intrinsically safe materials and processes.

Every cable assembly must also undergo continuity testing to confirm that no conductor breaks exist, followed by isolation checks and insulation resistance measurements to verify dielectric strength. Crimped contacts should also be subjected to pull-force tests and visual inspections in accordance with IPC/WHMA-A-620 standards. This combination of mechanical and electrical verification ensures that terminations will endure sustained vibration and shock loads, whether mounted in an engine bay, exposed to saltwater spray on a vessel or operating continuously in a factory environment.

When to opt for custom cable assembly

When off-the-shelf harnesses can’t meet specific space constraints, environmental requirements, unique connector layouts or hybrid signal/power needs, OEMs turn to custom cable assembly solutions.

Key drivers for customisation include:

- Form-factor constraints. Tight spaces in automotive dashboards or compact marine instruments may require angled, overmoulded assemblies that fit precisely into enclosures.

- Mixed signal and power. Combining high-voltage power lines with low-voltage sensors or data lines requires careful shielding and separation within the same harness to prevent noise coupling.

- Prototyping low-volume runs. Early-stage designs often need prototype cable assemblies built to evolving specifications. A reliable electronics manufacturer can iterate quickly, offering fast-turn services so OEMs can validate form, fit and function before committing to large volumes.

- Batch traceability and serialisation. In industrial or safety-critical automotive applications, each cable may require a serial number or trace code for quality records, warranty claims or field service maintenance.

Before specifying a custom cable assembly, you should work with your engineering and sourcing team to define pin-outs, conductor sizes, jacketing materials and connector types. Early collaboration with an electronic contract manufacturing partner can also surface manufacturability concerns — such as for overmoulded junctions or crimp tolerances for high-density connectors —well before production, reducing the risk of recalls or rework.

The role of electronic contract manufacturing in cable assembly

As you expand product lines and face tighter time-to-market pressures, outsourcing cable assembly to an experienced electronics manufacturing services partner can deliver cost, quality and logistical advantages. Below, we outline the benefits of electronic contract manufacturing and key supplier capabilities to evaluate.

Comprehensive supply chain management

An electronic contract manufacturing provider typically manages vendor relationships for raw wire, connectors, housings and shrink tubing. Consolidating these sources under one roof reduces lead times and eliminates the need for you to juggle multiple purchase orders.

Expertise across connector and cable technologies

Leading electronics manufacturing services providers will maintain a broad portfolio of connector brands, cable types (coaxial, twisted pair, multi-core, ribbon) and termination equipment. This expertise lets you choose the optimal solution for signal integrity, mechanical durability and environmental sealing.

Scalable production capabilities

From prototype cable assemblies in single–digit quantities to high-volume production runs (thousands to tens of thousands of units), an electronic contract manufacturing partner can scale resources — including skilled labour, capital equipment and quality systems — to meet demand fluctuations without capital investment.

By using volume purchasing, process automation and established vendor contracts, contract electronics manufacturers can also lower your per-unit costs.

Consistent quality management

Certified electronics manufacturing services providers adhere to industry quality standards (including IPC/WHMA-A-620, ISO 9001, ISO 14001, ATEX, RoHS and REACH). They will also have robust process controls — such as crimp force monitoring, pull-test fixtures and 100 % visual inspection — to ensure each cable assembly meets specifications.

What to look for in a cable assembly supplier

When evaluating potential suppliers for cable assembly, you should look for specific capabilities that signal maturity in process and engineering support. Here are five key points to consider when choosing an electronics manufacturer for cable assemblies:

- Connector and cable portfolio depth. Ensure the supplier stocks or can source all the connectors and speciality cables (shielded, double-jacketed, high-flex) you need for your application.

- Termination and overmoulding capabilities. Ask if the electronics manufacturing services provider offers both overmoulding and low-pressure overmoulding. Overmoulded junctions improve mechanical strain relief and provide an IP67/68 seal. Low-pressure overmoulding is ideal for delicate connectors or PCB-mounted terminations where high injection pressures could damage solder joints.

- Testing and validation infrastructure. Look for in-house test equipment, such as continuity testers with automated logging, pull-test fixtures for crimped contacts, and environmental chambers for vibration, temperature cycling and salt spray. A supplier that integrates incoming-inspection and final-test stations into the workflow can quickly catch defects before assemblies ship.

- Certifications and regulatory compliance. Certifications such as ISO 9001 indicate a mature quality management system. You should also look for a supplier that can provide cable assemblies to IPC/WHMA-A-620 Class 3, particularly if you’re developing high-reliability or mission-critical products.

- Engineering and design support. See if the supplier offers design-for-manufacturing (DfM) reviews, tooling recommendations and tolerance analyses. Early engagement helps avoid costly redesigns — especially for custom cable assembly solutions that require unusual connector orientations or multi-media capabilities (for example, both fibre optic and copper wires within one harness).

Why choose EC Electronics for cable assembly?

At EC Electronics, we provide a complete cable assembly service — from design, drawing and prototyping through to full production volume.

With 40 years of experience in electronics contract manufacturing, we have considerable knowledge across a wide range of connectors, cables and terminating equipment from all the major suppliers. We are continuously working to industry best practices, including IPC/WHMA-A-620 Class 3 Standard, and our dedicated cable assembly facilities can fulfil production requirements for any cable assemblies and for any volume requirements.

Our most popular cable assembly services include:

- Cutting and preparing wires. Our fully automatic Komax 255 and wire processing machines cut, strip, tin dip and crimp single or multi-core wires.

- Crimped cable assemblies. We hold a vast range of automatic connector and crimp tooling for all major manufacturers, including TE Connectivity, Molex, Amphenol, JST, ITT Cannon, DEUTSCH and Hirose.

- Cable looms and harness assembly. Applications range from simple panel wiring to complex interconnect harnesses for a wide range of industries, including the industrial, automotive and marine sectors.

Whether you are looking to be more competitive in your market or respond to short-term fluctuations in demand, we can help.

Contact EC Electronics today at +44 (0)1256 461894 or sales@ec.local to discuss your next cable assembly project and obtain a free quote.