Original equipment manufacturers (OEMs) must focus on their core competencies to remain competitive.

For many OEMs, outsourcing non-core functions, such as electronics manufacturing, has become an effective strategy for enhancing operational efficiency and reducing costs. Electronics manufacturers offer many services, but electronics box build — the complete assembly of an electronic product beyond the production of printed circuit boards — is a particularly valuable solution.

In this article, we look at why you should partner with a box-build electronics supplier for these services, outsourcing this critical aspect of production to streamline the manufacturing process for your business.

What are the benefits of electronics box build for OEMs?

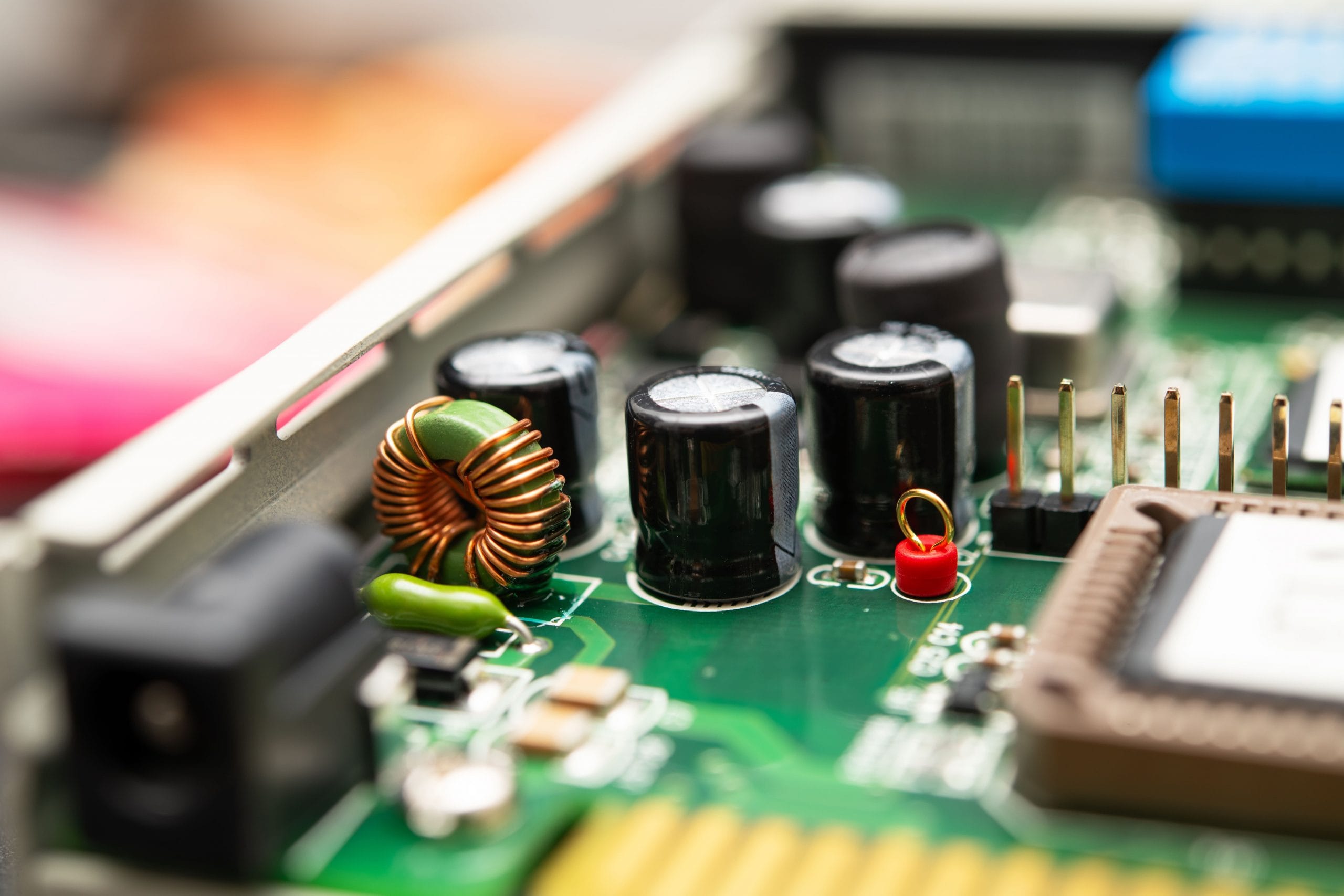

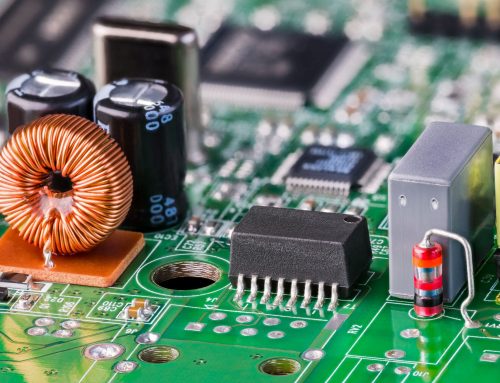

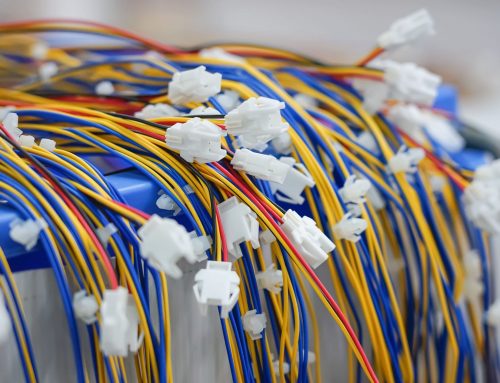

The electronics box build process includes enclosure assembly, cable assembly, wire harnesses, installation of subassemblies and system-level testing. Essentially, it encompasses all the steps needed to produce a fully functional, end-user-ready product.

For OEMs in industries such as healthcare, transportation and security, outsourcing these electronic manufacturing services to a trusted box-build electronics manufacturer offers numerous advantages. Here are six key benefits:

1. Streamlined supply chain

Managing a complex supply chain can be time-consuming and expensive. Outsourcing to a box-build electronics supplier consolidates multiple production stages under one roof. This eliminates the need to coordinate with multiple vendors for different components, reducing logistical challenges and lead times.

By working with an experienced electronics manufacturer, you can gain access to a full turnkey solution — from component procurement and assembly to final packaging and distribution. This simplifies operations and ensures every step of the process is seamlessly integrated, leading to improved efficiency and cost savings.

2. Improved quality control

Quality is a critical concern for OEMs, particularly in industries such as healthcare and security, where product reliability is non-negotiable. A reputable box-build electronics manufacturer will employ stringent quality control and assurance measures at every stage of production.

By outsourcing the electronics box build process, you can ensure your products meet the highest industry standards. From the sourcing of high-quality components to rigorous system-level testing, an experienced electronics manufacturing partner will have the expertise and infrastructure to deliver consistent, reliable results.

3. Cost efficiency

Outsourcing to a box-build electronics supplier can significantly reduce your manufacturing costs. Experienced suppliers take advantage of economies of scale to procure components at competitive prices. Additionally, their specialised expertise minimises waste and inefficiencies in the production process.

You can also save on overhead costs by eliminating the need to maintain in-house manufacturing facilities or invest in specialised equipment, allowing you to allocate resources to other strategic priorities, such as research and development or marketing.

4. Scalability and flexibility

Demand can fluctuate significantly depending on the season, market and various external factors. Managing these changes in-house can be challenging and costly. Outsourcing electronics manufacturing services provides you with the scalability you need to adapt quickly to changes in demand.

A box-build electronics manufacturer with an extensive network of suppliers and dedicated facilities can easily ramp up or scale down production volumes based on your requirements. This flexibility ensures you can meet market demands without overextending your resources or risking stock shortages.

5. Access to expertise and innovation

Partnering with a specialised electronics manufacturer gives you access to a wealth of expertise and cutting-edge equipment. These manufacturers stay up to date with the latest advancements in electronics manufacturing, ensuring you benefit from innovative solutions and best practices.

For example, experienced electronics box build providers will be adept at optimising designs for manufacturability, which can improve product performance and reduce costs. This technical knowledge can also help you overcome design challenges and bring products to market faster.

6. End-to-end solutions

Many box-build electronics suppliers offer comprehensive, end-to-end solutions that go beyond assembly. This includes services such as packaging, labelling and even direct shipping to end customers. These capabilities simplify logistics, enabling you to deliver products faster.

By entrusting the entire process to a reliable partner, you can focus on your core business activities whilst ensuring your products are delivered to market on time and to specification.

Why choose EC Electronics as your electronics box-build supplier?

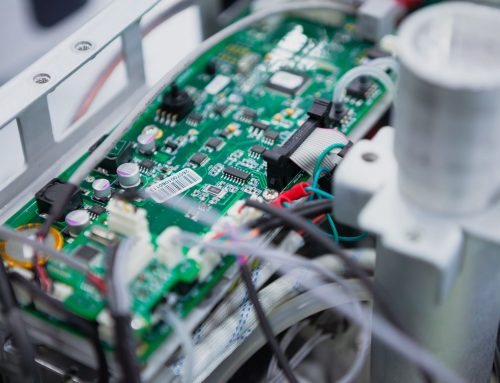

At EC Electronics, we specialise in providing high-quality electronics manufacturing services tailored to the needs of OEMs across a range of industries. As a trusted box-build electronics manufacturer, we offer a full turnkey supply chain solution, encompassing everything from component procurement and production to testing, packaging and even shipping to the end customer if required.

Our state-of-the-art facilities and experienced team ensure every electronics box build project is completed to the highest standards of quality and efficiency. Whether you need a small batch of custom assemblies or large-scale production runs, we have the expertise and resources to deliver.

Ready to streamline your manufacturing process, reduce costs and enhance product quality? Contact us today at sales@ecelectronics.com to learn more about outsourcing your electronics box-build requirements to an electronics manufacturer like EC Electronics.