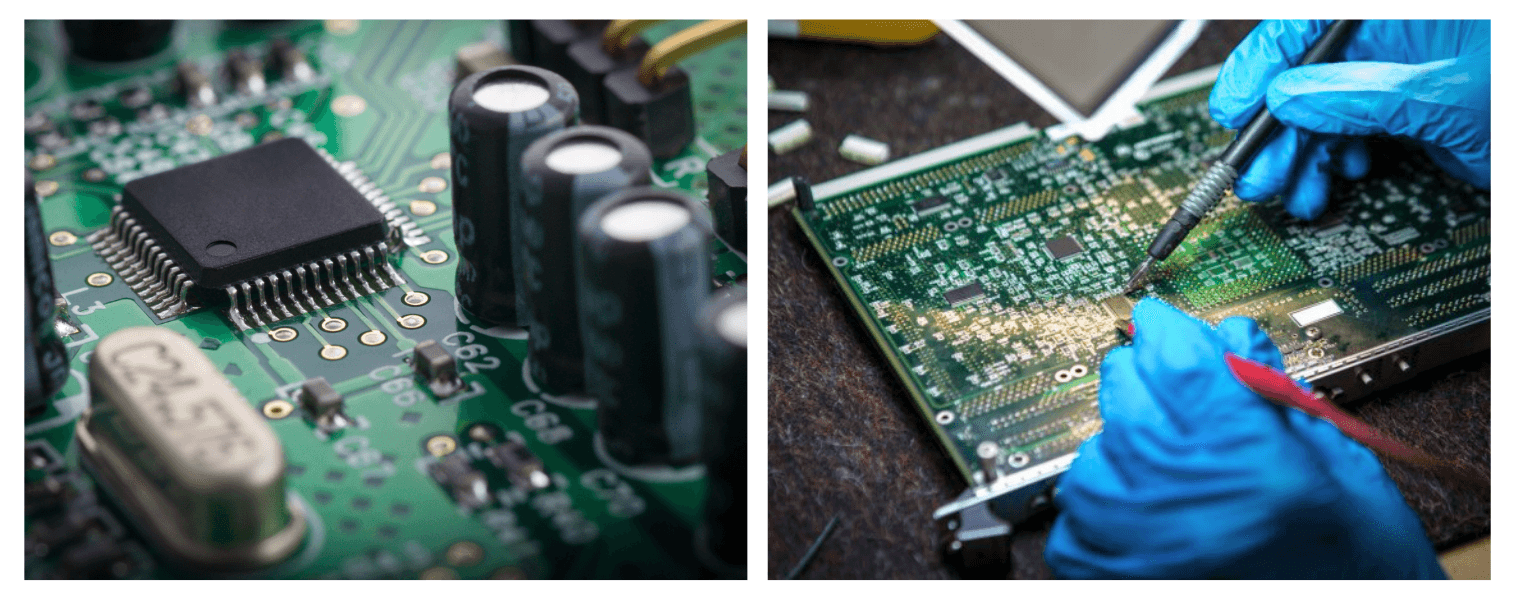

Reliable & Cost-Effective PCB Assembly Services for OEMs — from Prototype to Full Production

Looking for a printed circuit board manufacturer to bring your products to market faster and more cost-effectively (without sacrificing quality)?

Our PCB assembly services help you reduce time-to-market, scale efficiently and improve product quality — whether you’re prototyping or managing full-scale production.

With 40+ years of experience in manufacturing printed circuit boards, we support OEMs with flexible, end-to-end solutions that simplify your supply chain and ensure the consistent performance of your PCB assembly.

You need our PCB assembly services if you want to:

- Accelerate product launches. From design support to testing, we help you get to market faster with fewer production headaches.

- Cut production costs. Our international footprint and component sourcing capabilities reduce overhead without compromising quality.

- Improve product reliability. Every board undergoes thorough testing (including AOI, ICT and functional tests) to ensure optimal performance.

- Scale seamlessly. Whether you need low-volume PCB assembly for prototyping or high-volume manufacturing, we adapt to your needs — fast.

Advanced PCB assembly services to meet your exacting standards

We use the latest equipment in our PCB assembly services, encompassing both surface-mount technology (SMT) for precise component placement and through-hole assemblies for robust connections in critical applications.

This means we can manufacture a range of printed circuit boards for you — from initial prototypes through to a complex, multi-technology PCB assembly.

Our PCB assembly capabilities include:

- Four automatic YAMAHA SMD pick-and-place lines. These high-speed machines ensure precise and efficient placement of surface-mount components when manufacturing your printed circuit boards.

- Forced air convection reflow soldering. This advanced soldering process provides uniform heating to ensure optimal solder joints — even for complex or high-volume PCB assemblies.

- Automatic optical inspection (AOI). Our AOI systems rapidly and accurately inspect solder joints, components and circuitry — guaranteeing your PCB assemblies are defect-free before further processing.

- Lead-free wave soldering. Our lead-free wave soldering technology is used for through-hole components, offering you a reliable and environmentally friendly solution while maintaining exceptional solder joint quality.

- Conventional hand assembly. If your project requires through-hole components, low-volume runs or intricate soldering tasks, our skilled technicians will assemble by hand.

- ATE/ICT electrical test. We use automated test equipment (ATE) and in-circuit testing (ICT) to verify the functionality and integrity of your assembled PCBs, identifying potential issues and ensuring optimal performance.

- Conformal coating. To protect your PCB assemblies from environmental factors (such as moisture, dust and chemicals), we apply conformal coatings that enhance durability and extend the lifespan of your assembly.

- Potting and encapsulation. If you require enhanced protection against extreme conditions, our potting and encapsulation services shield sensitive components from vibration, shock and harsh environments.

We understand how critical a reliable printed circuit board manufacturer is to your product’s success.

Fill in the form now to speak to our skilled engineering and NPI teams about your project requirements and get a quote for our PCB assembly services.