Overmoulding Tool Design, Creation, and Logistics for Electronics Assemblies

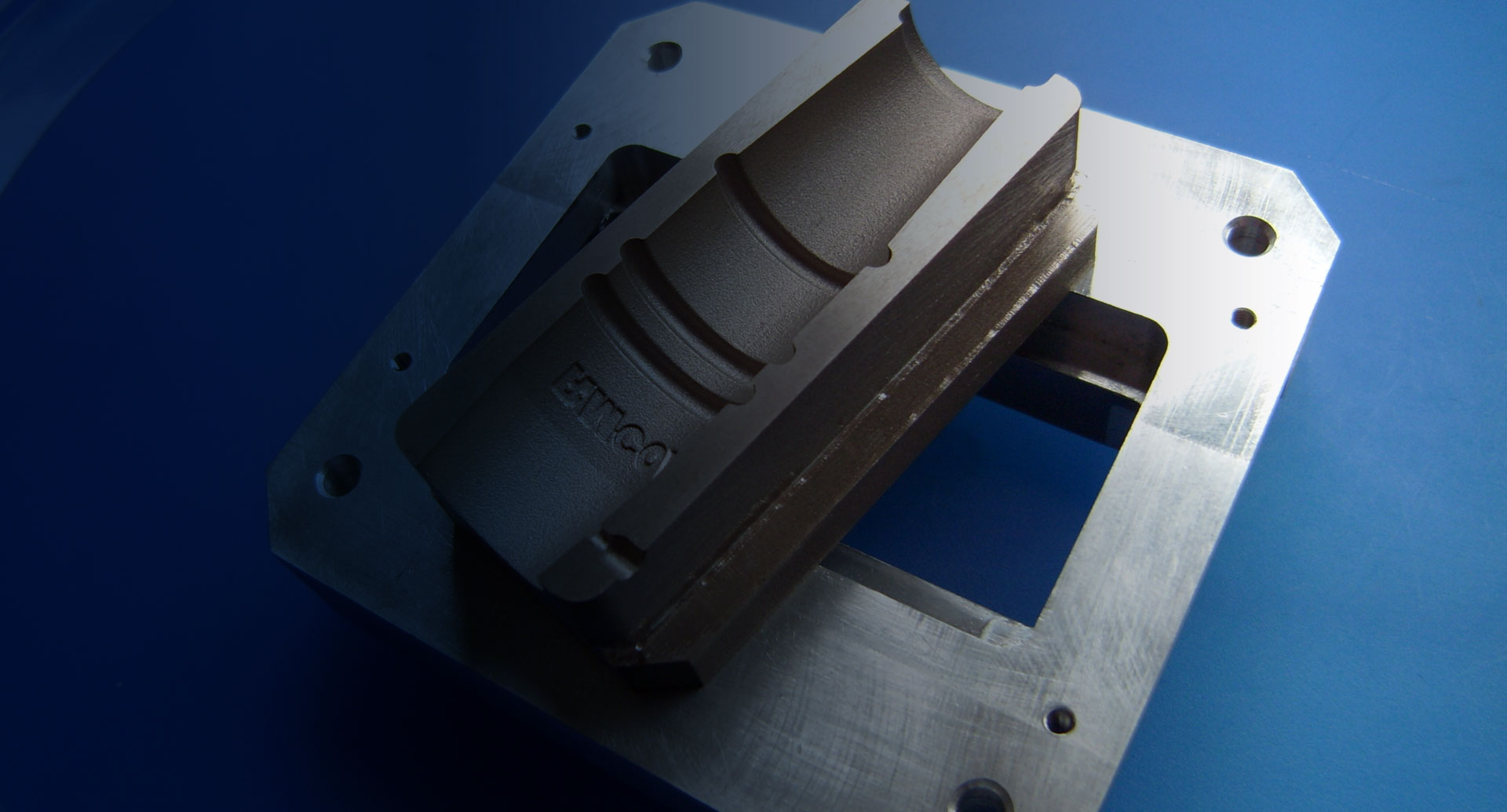

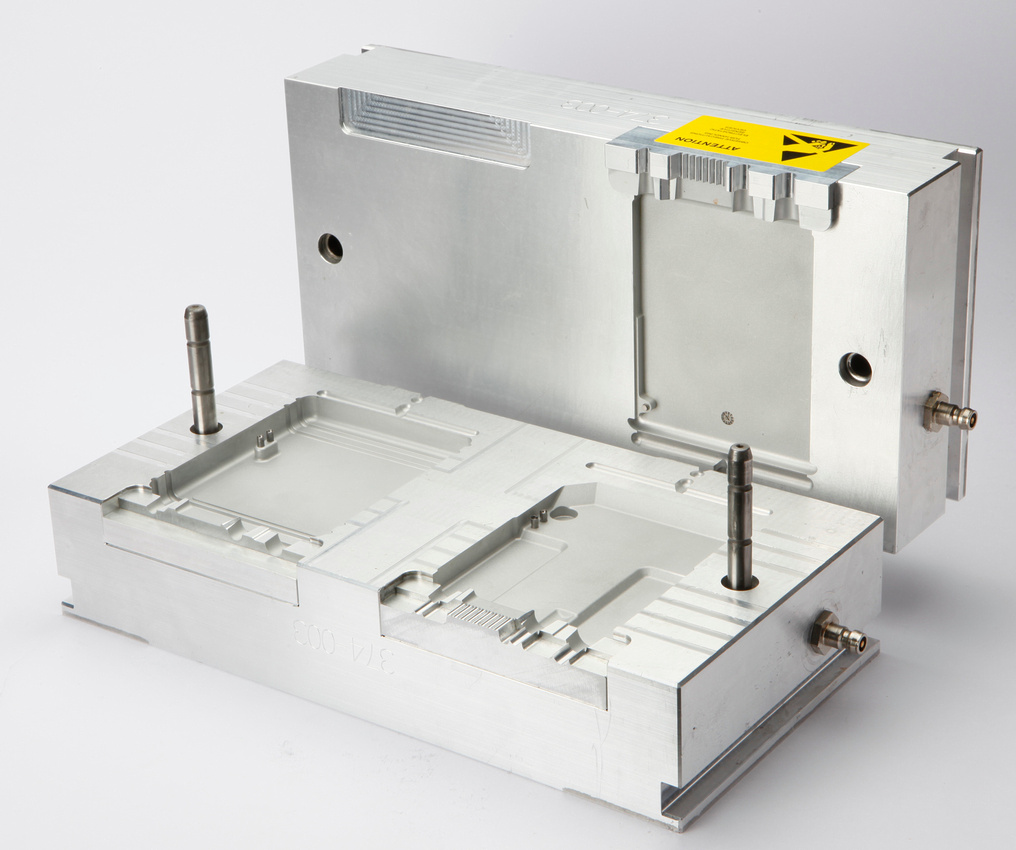

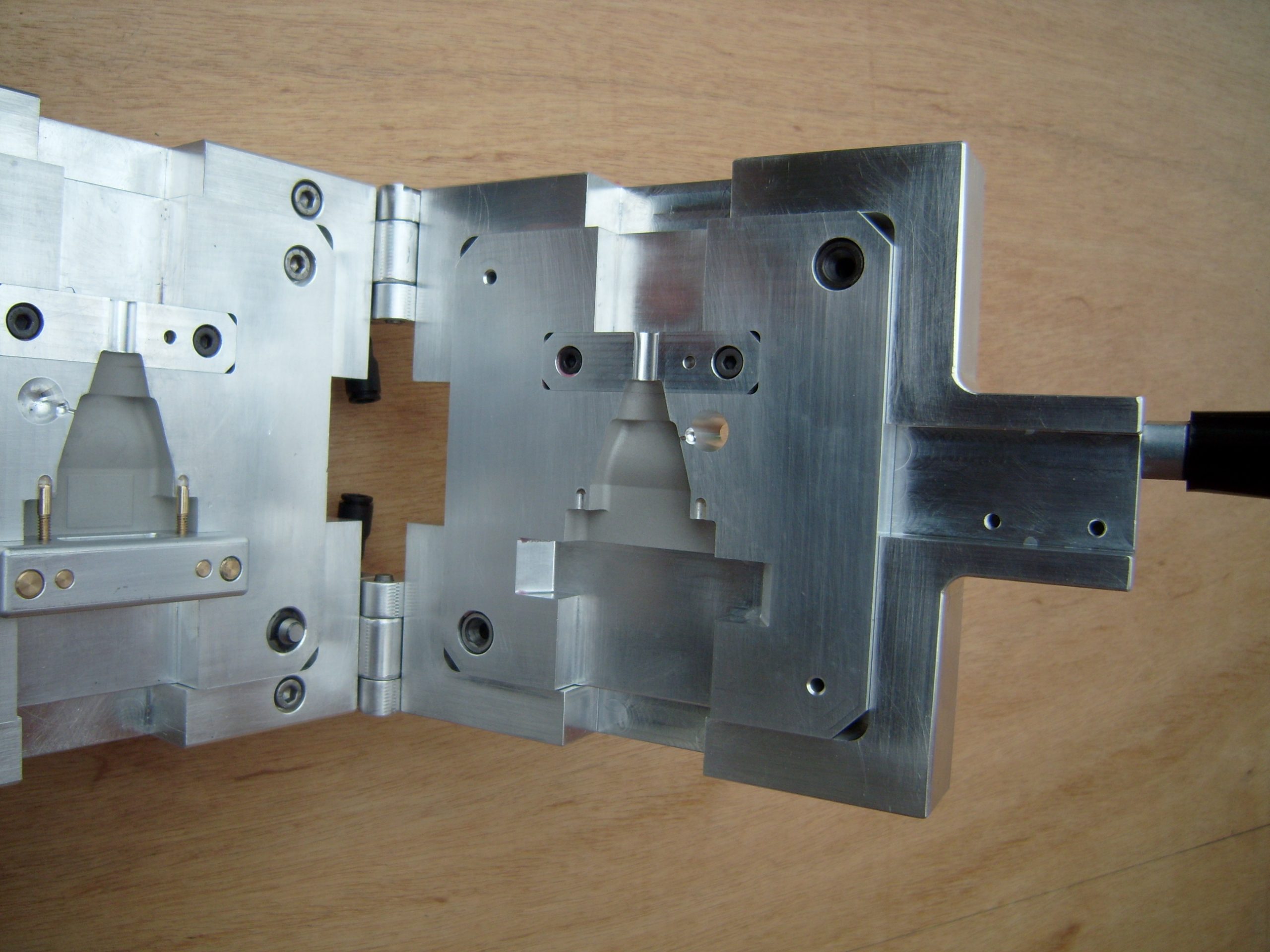

A moulded part only looks as good as the tool that shapes it. That’s why we never compromise on the design, manufacture, or quality of our overmoulding tools. Our team delivers expert tooling and design services for electronics assemblies.

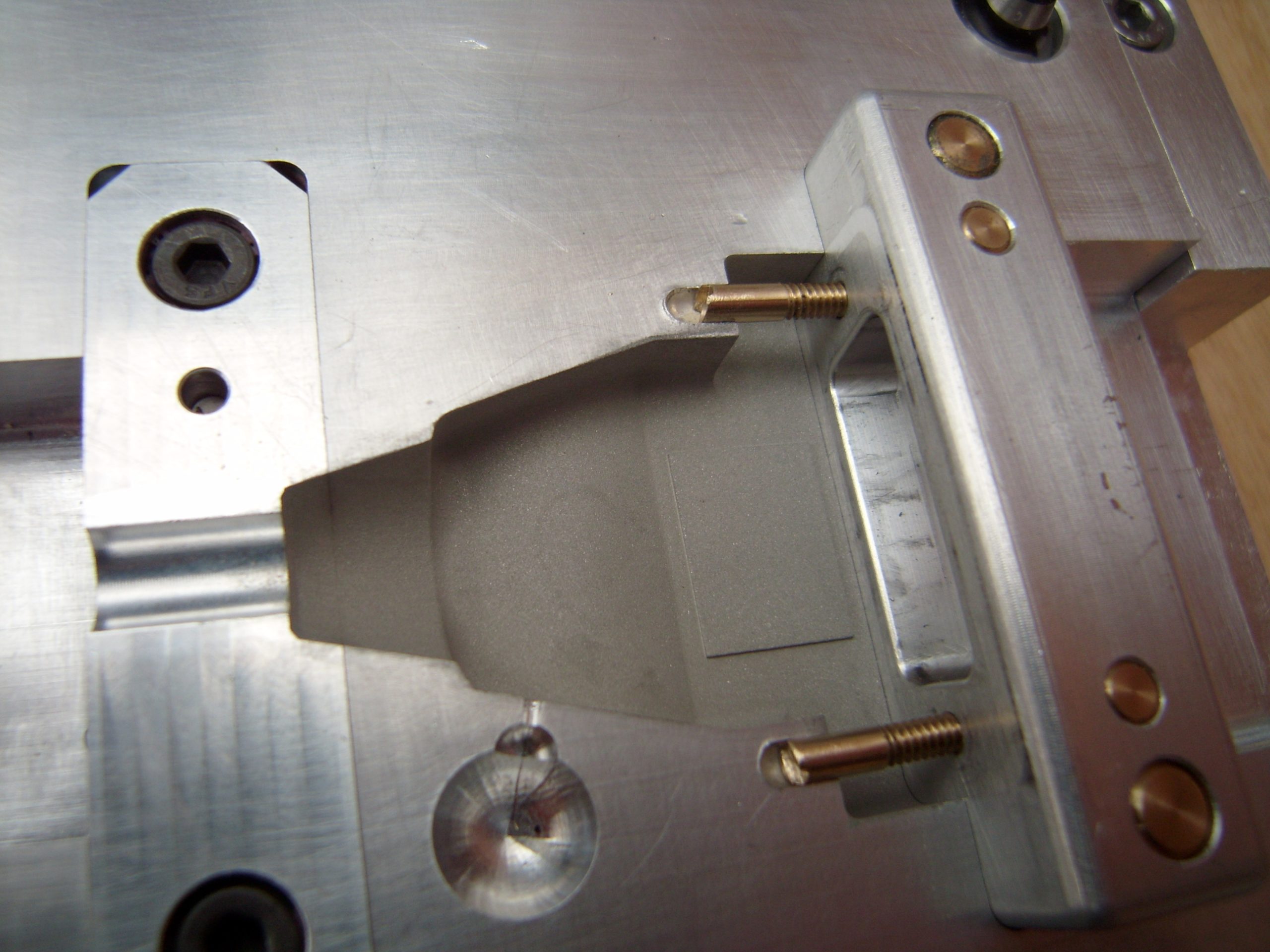

Whether you need prototyping, development, or production, we commit to building durable, high-quality tools. Each toolset is engineered for maximum value and performance, which is why we use aluminium moulds that give you cost-efficient, purpose-built tooling.

Our expertise

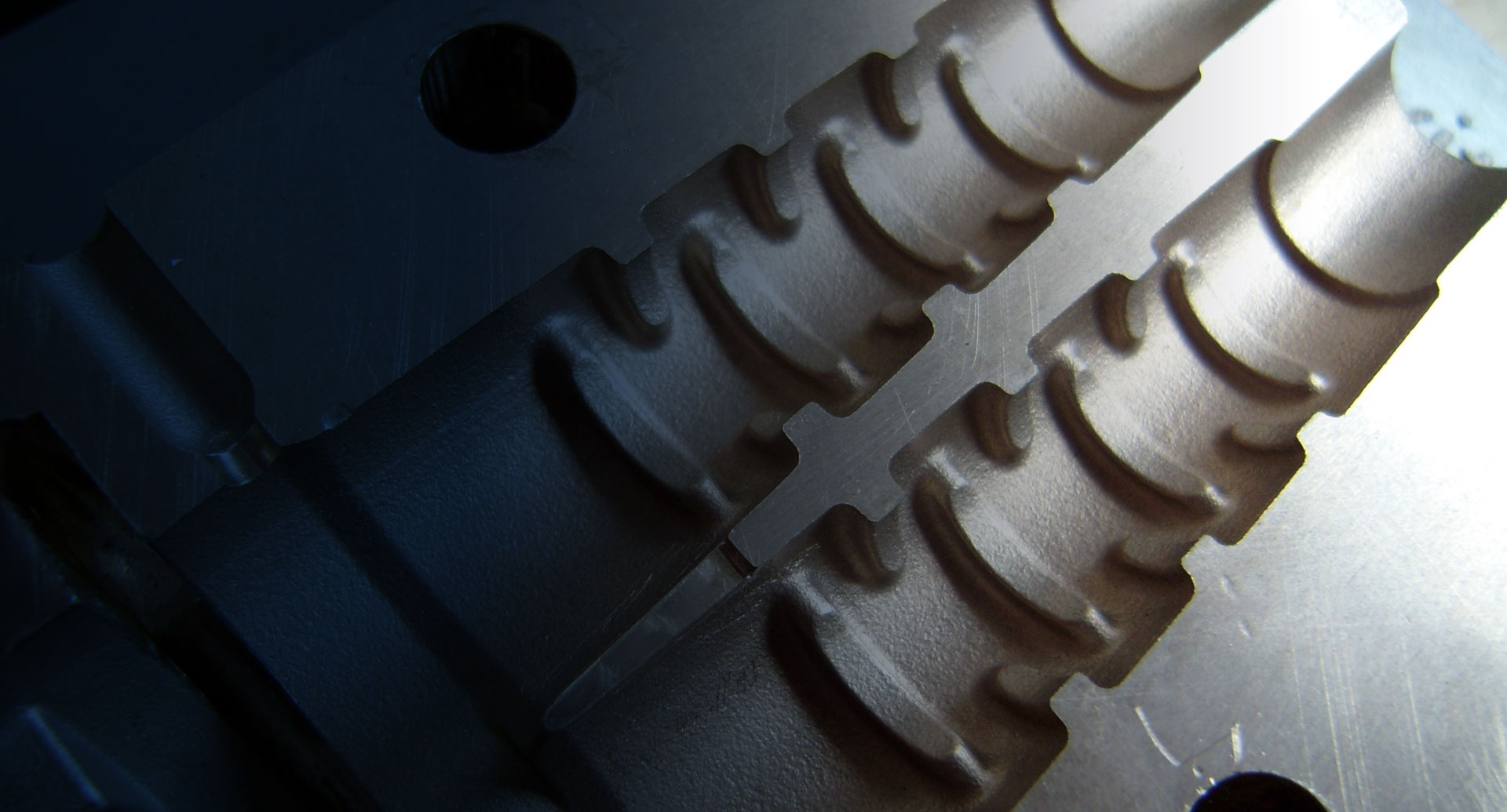

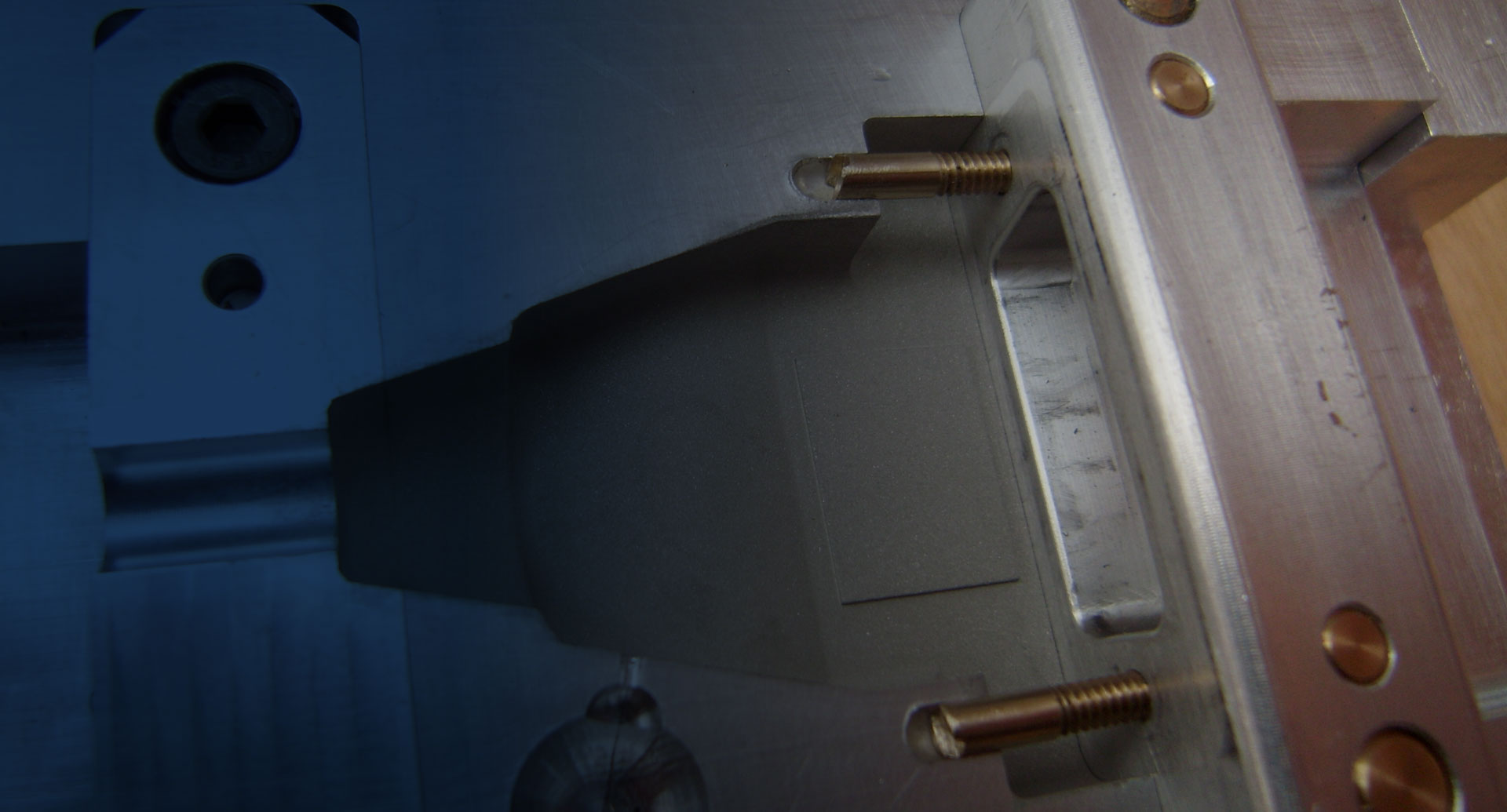

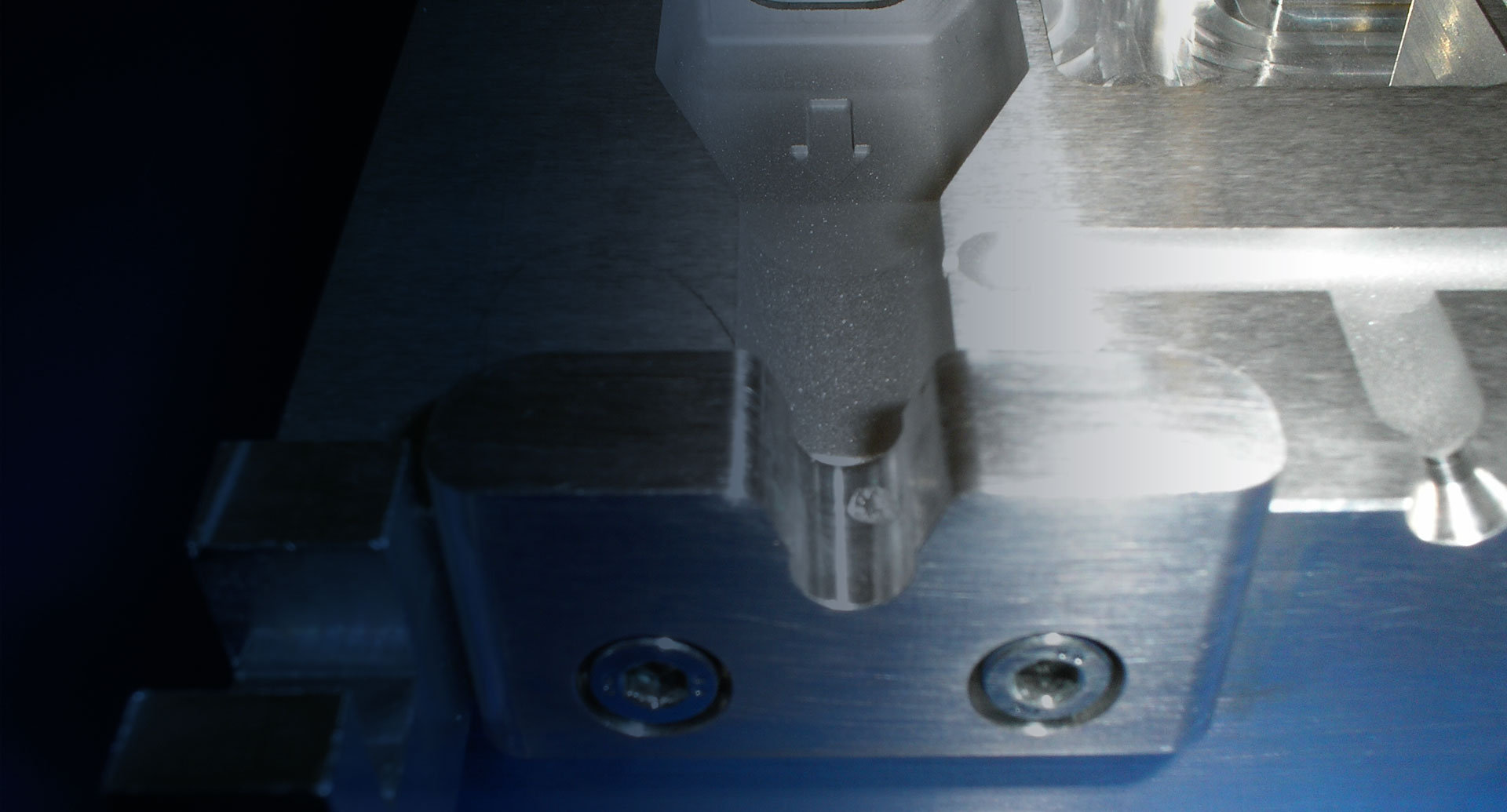

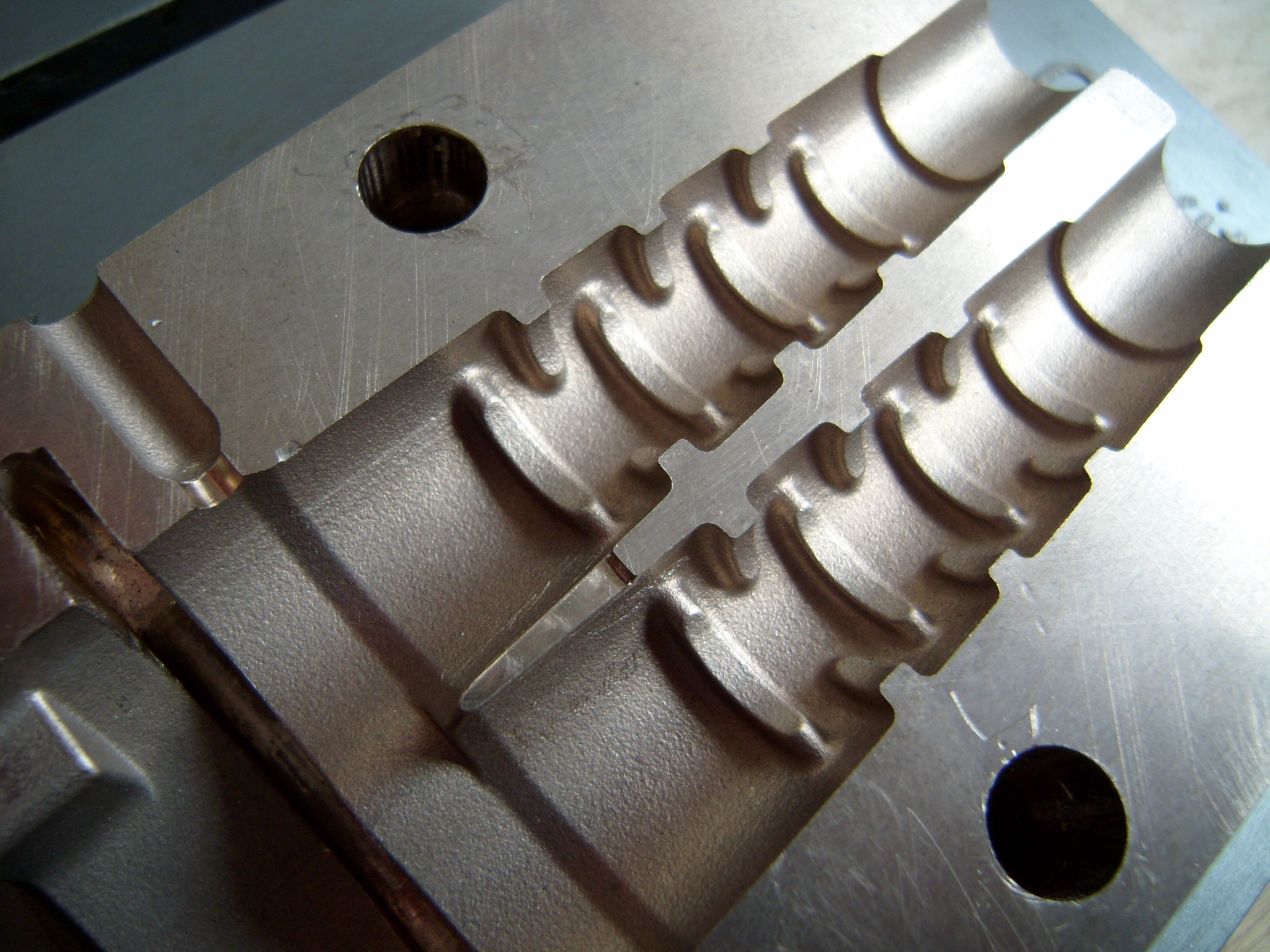

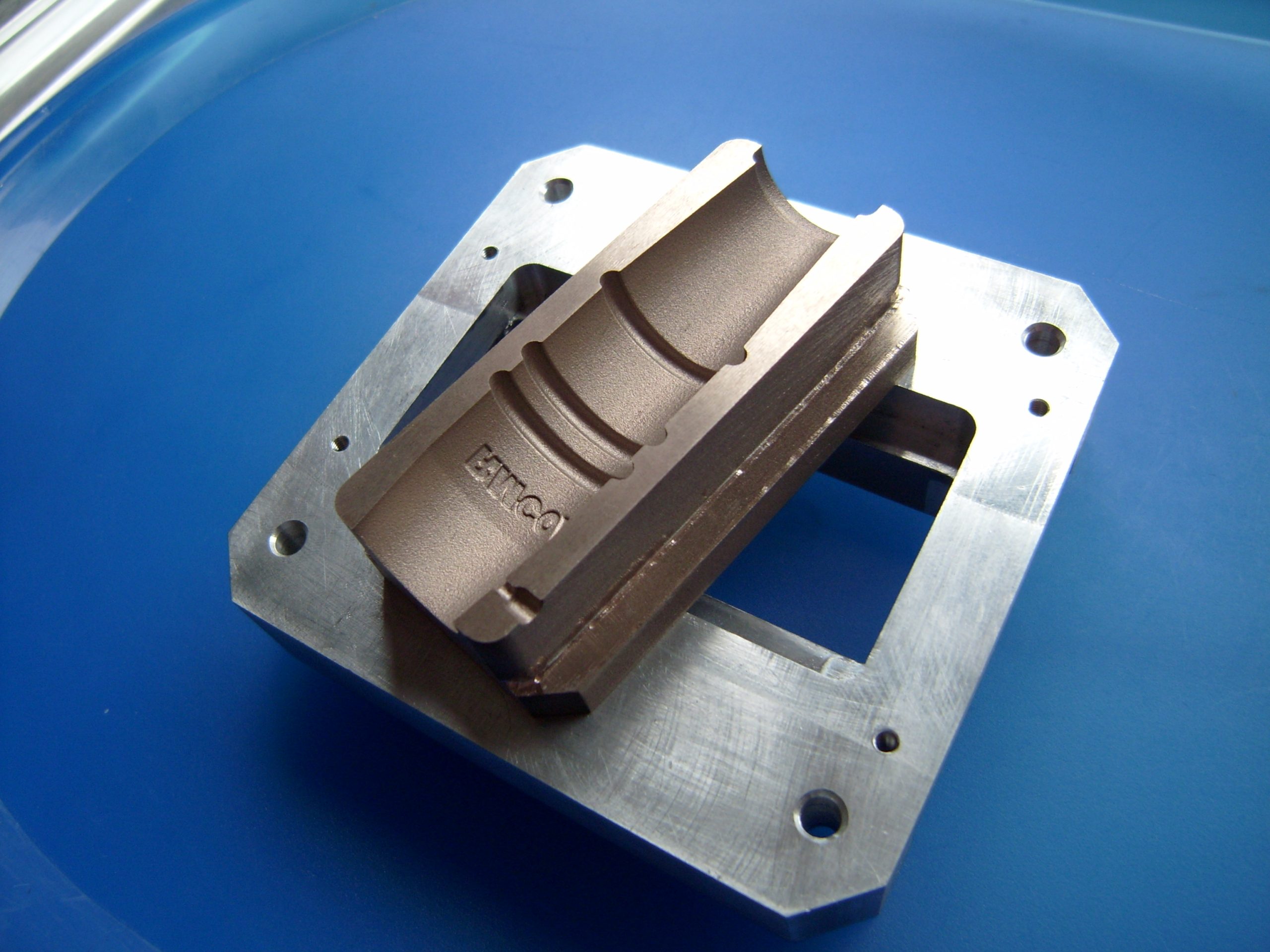

Our toolmaking specialists have worked with low-pressure overmoulding tools worldwide since the process emerged in the mid-90s. We produce precision mould tools by importing 3D CAD model data using the STEP (ISO 10303) standard and linking it directly with our state-of-the-art four- and five-axis CNC mills.

We work to tolerances measured in microns and create bespoke tools whenever required. Even if you only have the parts, our team can design overmoulding tools without drawings. Material selection is based on performance criteria, and we interpret each material’s rheology (flow behaviour) to choose the best option. Together, these steps form part of the expert tooling and design services we deliver for high-quality overmoulding solutions.