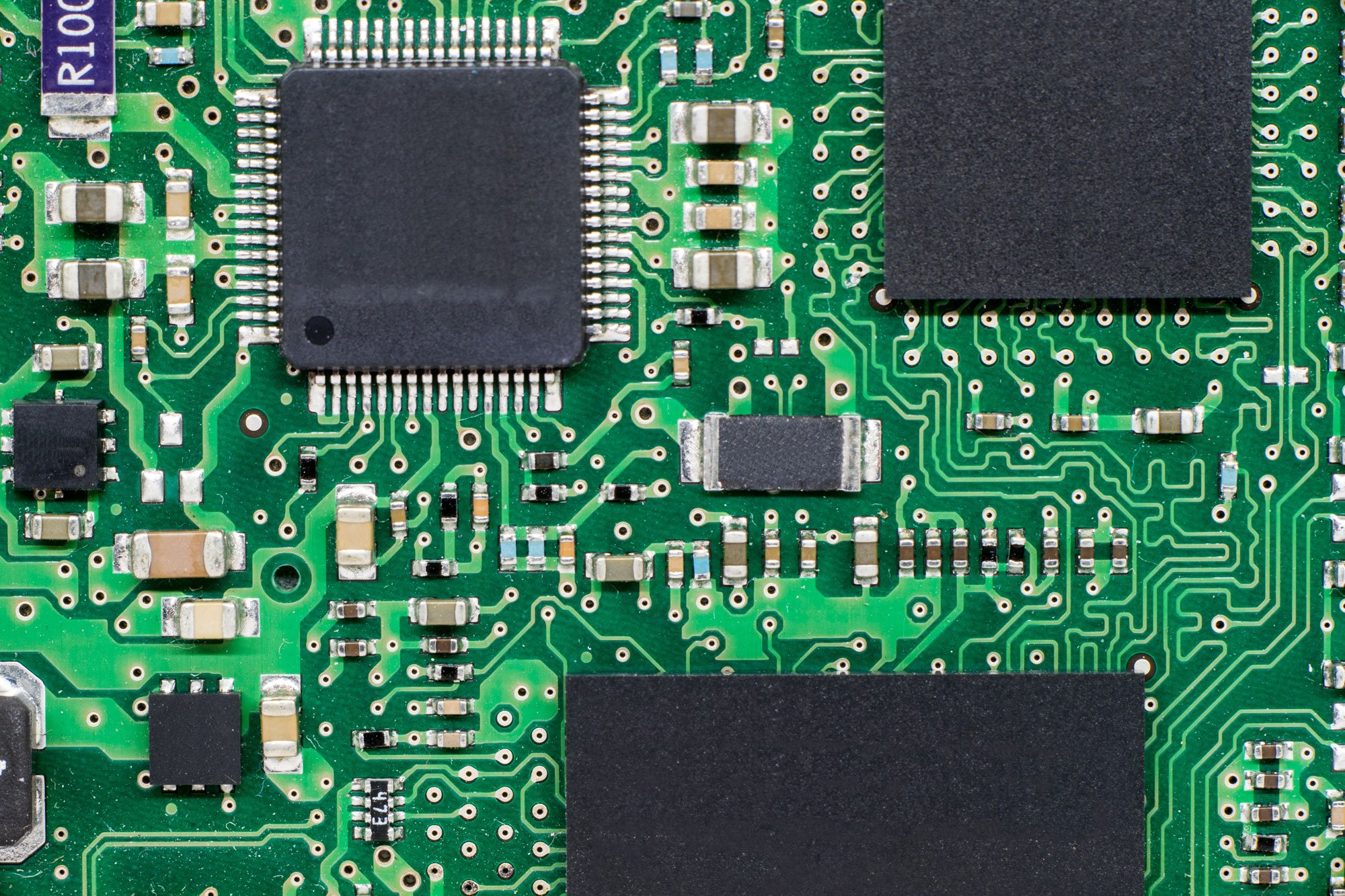

Potting, Encapsulation and PCB Conformal Coating

PCB conformal coating

Where a higher than normal level of protection is needed for components and circuits, we offer PCB conformal coating as an added-value service. We also pride ourselves on working to the highest possible safety standards, and our plant includes full fume extraction facilities.

Conformal coating is ideal for lightweight devices or if you require printed circuit boards with a precise thickness to be fitted into smaller devices.

Backpotting and encapsulation

To protect products from environmental hazards and ensure product design security, we provide a variety of backpotting and encapsulation processes. Potting and encapsulation are particularly useful for protecting PCBs which need to go through high-speed and high-volume production and assembly lines.

Our specialist facility enables us to encapsulate or backpot a wide range of PCBs as well as connectors and interface box assemblies. Selection of the right compound is crucial here, and we can advise on how to ensure both optimum performance and value for money.

Key applications

- Protect electronic and electrical components

- Sensor assemblies

- Power supplies

- PCB encapsulation

- Transformers

- Other critical electrical, electronic equipment

- Pot or encapsulate cable joints, junctions

Why EC Electronics?

We want to ensure that your products are protected from the elements, and our specialist facility provides the expertise and equipment to do just that.

As an ATEX-certified manufacturer, we guarantee all electrical products are suitable for use in high-risk, high-pressure and potentially explosive atmospheres in line with IECEx and ATEX Directive 2014/34/EU. We are proud to work to the highest safety standards and provide an equally high quality of work to projects of any size and complexity.

You can rely on us for your PCB conformal coating needs — we are with you every step of the way.