The complexity of global supply chains depends largely on what and how much you’re sourcing. With some materials — like paper — you’ll find a suitable supplier almost anywhere in the world.

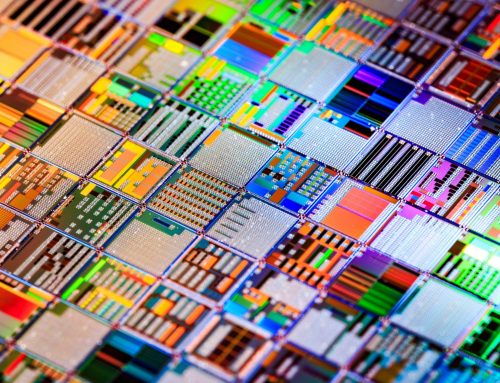

However, in the electronics industry, things are not so straightforward. Multiple commodities from multiple suppliers across various geographic locations mean global electronics supply chains are much trickier to manage.

One of the main challenges of electronics is the sheer volume of parts that go into one product. Some of these parts also need to have approvals, and suppliers will require certain certifications. Bespoke parts are often manufactured to specific designs, too — meaning rigorous testing and sampling are necessary to ensure they meet meticulous quality standards.

Why is a stable supply chain so important?

A good supply chain is all about remaining competitive. If a customer comes to you wanting a specific part for a project, you need to know that you can deliver through a trusted chain of suppliers. As such, having a range of approved global suppliers is key to ensuring you never have to reject new enquiries.

A strong network of suppliers also allows you to free up capacity and manufacture a range of products more cost-effectively (and at short notice) — which, ultimately, translates to a better price for the customer. This is why so many companies in the electronics sector will have at least some offshore suppliers.

However, supplier selection is crucial. It’s not enough to have a good website or a good booth at an exhibition — you need to see the factory and the quality of the parts they produce first-hand. When customers place orders, you need to know exactly where their products are coming from.

It’s also important not to cast the net too wide. Once suppliers are spread out too far, the chain becomes more difficult to manage, and you lose control of where the materials come from. Instead, it’s crucial to build long-term partnerships with suppliers that share and uphold your ethos, integrating them into your business to ensure a fluid process.

What is the impact of external factors?

A stable supply chain is based on control. When something happens in one part of the supply chain, it tends to have a knock-on effect on other aspects. But what happens when external factors outside of your control occur?

Lately, there’s been a lot of focus on how the coronavirus pandemic has been affecting supply chains — particularly in China. While factory capacity was reduced for a short period, they were able to open again relatively quickly. The main issue now is that China focuses predominantly on overseas customers, many of whom won’t be in a position to place orders at the moment. The cost of freight has also skyrocketed due to limited flights and sailings, with some operators charging double or triple what they did pre-coronavirus.

However, although the virus has dominated news headlines, for a lot of suppliers and customers in China and the US, the trade war will be a more pressing issue. The US trade tariffs on goods coming from China mean many companies are struggling because they’re no longer receiving orders from US customers. Yet, far from bringing manufacturing back to home soil, many companies are instead looking to Vietnam or the Philippines, where they can get goods manufactured without being hit by the trade tariffs.

Then there is also the issue of Brexit, which — like the US trade tariffs — is likely to have more significant long-term impacts for companies operating in the UK and Europe. The main issue in this area will be the movement and taxation of goods, rather than demand or sourcing materials. As such, many UK companies may choose to move warehouses and operations to Europe to avoid paying excess duty or tedious customs checks and speed up shipping for customers.

What does the future hold for supply lines?

It would be easy to assume that supply lines from China to Europe will take a substantial hit following the coronavirus. In reality, many companies are unlikely to pull out of China and start sourcing materials from elsewhere. The products coming out of China are stable, and it’s difficult to find that quality at that price anywhere else.

Some US-based manufacturers might look to suppliers elsewhere in Asia to avoid being stung by the trade tariffs. But there are risks of using suppliers from countries like Vietnam and the Philippines, which tend to be more unstable. In comparison, China has a strong business-focused infrastructure. Much of the technical knowledge and skillset — which has been lost in Europe and the US following the rush to close manufacturing in the West about 20 years ago — is also there.

Brexit is likely to see more movement of supply lines within Europe, as countries move their operations from the UK to countries within the EU.

Environmental and ethical issues could also have an impact on future supply chains, as customers start to demand more from the companies they do business with. As a result, both manufacturers and suppliers will need to start looking more closely at how they’re sourcing and moving their products, as well as the conditions they’re made in.

At EC Electronics, we’ve been sourcing overseas for over 10 years, meaning our supply chain is well-established. We work with an approved supplier list, and we visit and audit all our supplier’s facilities before selecting them to ensure our high-quality standards are upheld. To find out more, please get in contact today.